Flat Belt Drive

INTRODUCTION

Whenever the power has to be transmitter from one shaft to another shaft ,flexible machine elements such as belts,ropes or chains are frequently used.pulleys are mounted on the shaft and a continuous belt or rope is passed over them .In belts and ropes, power is transmitted due to friction between the shaft is large,then belts,ropes,chains are used. For smaller distance, gears are used.The amount of power transmitter depends upon several factors such as velocity of the belt, tensions in the belt,mass of the belt,arc of the contact between the belt and the smaller pulley.

CLASSIFICATION OF DRIVES

- Flexible drives

- Belt

- Rope

- Chain

- Direct drives

- Gear drive

- Cam drive

Flexible drives

Flexible power transmission elements is known as flexible drives.since these elements are flexible so they are called flexible drives. they are used to short distance power transmission. wire and ropes can used to long distance power transmission systems

Flexible power transmission elements is known as flexible drives.since these elements are flexible so they are called flexible drives. they are used to short distance power transmission. wire and ropes can used to long distance power transmission systemsFlat belts

which flexible drive having flat surface it is called as flat belt drives,this types of belts have 16 as maximum velocity ratio, maximum speed of the belt is 35 to 110 (m/s),5% of slip there in flat belt drives , it is the high tension belt drive,flat belt drives are good in shock resistance,but belt drive required to dressing and the initial cost of the belt drive is low.

SELECTION OF BELT DRIVE

which flexible drive having flat surface it is called as flat belt drives,this types of belts have 16 as maximum velocity ratio, maximum speed of the belt is 35 to 110 (m/s),5% of slip there in flat belt drives , it is the high tension belt drive,flat belt drives are good in shock resistance,but belt drive required to dressing and the initial cost of the belt drive is low.

SELECTION OF BELT DRIVE

Selection of a belt drive depends upon:

- Power transmitted

- speed of driver and driven shaft

- Shaft relationship

- Service conditions

- Speed reduction ratio

- Center distance

- Positive drive requirement

- Space available

TYPES OF BELT DRIVES

Used with shaft arranged parallel and rotating in same direction

Open belt drive with one idler pulley

Used with shafts arranged parallel and when an open belt can not be used due to small angle of contact of the small pulley.Idler pulleys (also known as jockey pulleys) are provided to obtain high ratio and when the required belt tension cannot be obtained by other means

Open belt drives with many idler pulleys

Twisted belt drive

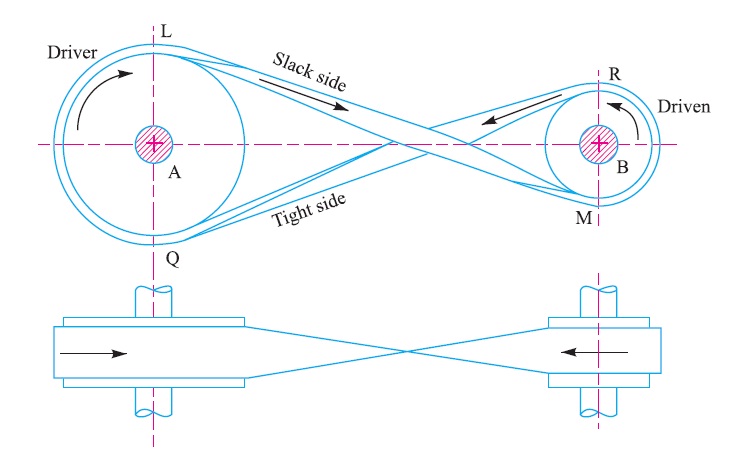

Used with shafts arranged parallel and rotating in the opposite direction

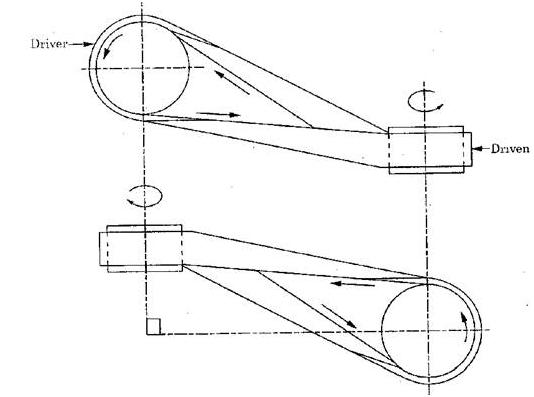

Quarter or quarter turn drive

Used with shaft arranged at right angles and rotating in one definite direction.

Quarter twisted belt drive with guide pulley

Quarter twisted belt drive with guide pulley

Used with shaft arranged at right angles when the reversible motion is desired.

Stepped of cone pulley drive

Stepped of cone pulley drive

Used for changing the speed of the driven shaft with the main or driving shaft runs at constant speed.

Fast and loos pulley

Fast and loos pulley

Used when the driven shaft is to be started or stopped whenever desired without interfering with the driving shaft.

Compound drive

Compound drive

Used when several units are to be driven from one central shaft

BELT MATERIALS

The desirable properties of a belt material are high coefficient of friction,flexibility,durability and strength. the main materials used for flat belts are:

- Leather belts:Leather belts are made of animal hides. the best quality leather is obtained from either sides of the backbone of a steer (bullock). leathers for belting may be tanned with oak,or chrome salts. Oak-tanned leather is fairly stiff, whereas chrome-tanned leather is soft and pliable. Belts are specified according to the number of layers.e.g.,single-ply,double-ply or triple-ply belts.

- Fabric and cotton belts:This belts are made by stitching together three or more plies (or layers) of canvas or cotton dock.The fabric is treated with linseed oil to make it water-proof.these belts are cheep. they are most suitable for farm work. quarry and saw mills.

- Rubber belts:This belts are made up of plies of fabric impregnated with vulcanized rubber or synthetic rubber.

- Balata belts: Balata belt is gum similar to rubber. Balata belts are made in the same manner as the rubber belts except that balata is substituted for rubber .these belts are acid proof and water-proof.the balata belts cannot be used at temperature above 40 degree C because at this temperature it begins to soften and becomes sticky.

- Nylon core belts:The nylon belt is the one of the composite material, it is the mixture or one or more dissimilar materials.

- Camel's hair belts:This is the belt with high efficiency

LOSSES IN TRANSMISSION AND EFFICIENCY

The losses in a belt drive are due to:

- Slip and creep of the belt on the pulleys (about 3%)

- Air resistance to the movement of belt and pulleys (usually negligible)

- Bending of the belt over pulleys

- Friction in the bearings of pulley (about 1%)

ADVANTAGES OF FLAT BELT TRANSMISSION

- Simple and economical.

- Parallel shafts no needed.

- Belt drives have jam production when overload.

- Noise and vibration are damped out .machinery life is increased because load fluctuations are shock absorbed.

- Belt drives are lubrication free.

- They requires low maintenance cost.

- They are very economical when the distance between shafts is very large.

DISADVANTAGES OF FLAT BELT DRIVES

- In belt drives,angular velocity ratio is not necessary constant of equal to the ratio of pulley diameters, because of slipping and stretching.

- Heat buildup occurs.speed is limited to usually 35 meters per second.power transmitted is limited to 370 kilowatts.

- Operating temperature usually restricted to 35 to 85 degree C

- Some adjustment of center of use of an idler pulley is necessary for wearing and stretching of belt drive compensation.

1 Comments

It was really informative! Thanks for giving such beautiful content about flat belt to understand. Keep posting it!

ReplyDelete