Costruction and working principle of diesel engine power plant

Diesel power plant

working principle:

The working principle of the diesel

power station is very simple; as we compress the air in a cylinder to raise the

temperature, then we burn the diesel

inside the engine and the combustion produces the working fluid at

high_temperature and high_pressure to convert the heat energy into mechanical

energy.

This working principle is a

working cycle done by the processes: intake, compression, expansion, and

exhaust.

Components of diesel power plant:

The diesel power station consists

of many components used to achieve the best of the plant let’s illustrate:

• Engine: it’s the main part of the plant

which used to produce power, it may be of the two-stroke or four strokes.

• Fuel supply system: it consists of a

storage tank where we store the oil supplied to the plant, all day fuel tank

where the oil pumped for usage, strainer which used to remove suspended impurities

of the oil, and fuel injection (transfer) pump which used to inject the clean

oil into the engine.

• Strainer: it’s used to remove solid

impurities from the oil transferred from the main tank to small dry tank

through this strainer.

• Air intake system: it’s used to remove

the dust particles from the atmospheric air to supply fresh air to the engine

for combustion, it may be dry (or oil) bath filter or oil immersed filter, and

it consists of pipes to supply the fresh air and filters to remove dust particles from the

air.

• Exhaust system: it’s used to remove the

exhaust gas from the engine to the atmosphere, and we also add a silencer to

this system to reduce the noise level of the system.

• Cooling system:it’s very important in the diesel power station to have a cooling system to maintain the overall temperature of the engine at an agreeable level, and this cooling system requires a water source, a water pump which circulates water through a cylinder, and cooling towers which used to cool the hot water.

• Lubricating system: it’s used to

minimize the wear of the rubbing surface of the engine as we store oil in a

main lubricating oil tank then draw this oil from an oil pump to pass through

the oil filter to remove impurities.

• Engine starting system: it’s used in

old conditions as a starter as it uses the air to push the engine and start an

initial rotation until the engine run with its own power, and the starting

methods may be:

a. Self_starters: which used in small

diesel engines where motor draws heavy current and designed to work for

continuously 30 Sec after it’s cooled.

b. Auxiliary engine: they are located

close to the main engine and driven through a clutch and gears as the clutch

disengaged to start the engine.

c. Compressed air system: which used in

large diesel engine and it ’s supplied from an air tank.

• Governing system: it’s used to control

the speed of the engine by changing the fuel provide according to engine load.

Diesel power plant

layout:

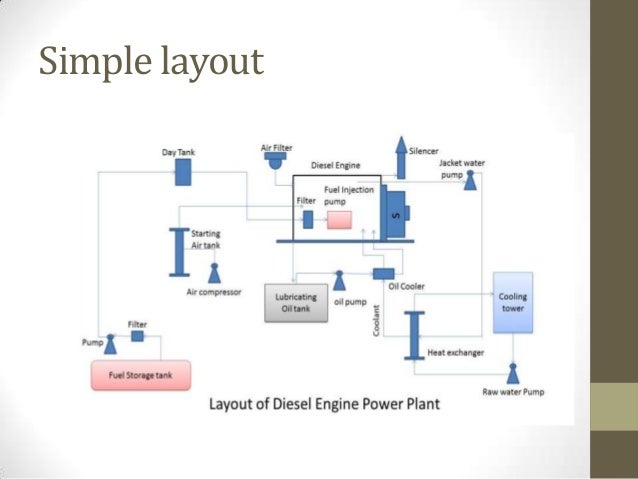

The layout of the diesel power

station illustrates the main and auxiliary components of the plant and the

importance of each component as:

• Diesel engine:known as compression ignition engine consists of a cylinder, cylinder head, piston, inlet valve, an inlet port, exhaust valve, valve spring, cooling fins, wrist fines, wrist pin, connecting rod, crankcase, crank pin, crank, and crankshaft.

And it’s classified

into a two-stroke engine and four-stroke engines.

• Engine starting system:It’s an arrangement to initially rotating the engine, we used a compressed air for starting the engine until it runs with its own power.

• Fuel handling system:We use trucks, railway wagons (barges) or oil tankers to deliver the fuel oil to the plant site, and we deliver the oil to the main tanks from engine day tanks which capable to store oil equivalent to 8-hour consumption through strainers.

And we heat the oil by hot water

or steam to reduce viscosity and in order reduce the pumping power input

• Fuel injection system:We can say that this system is the heart of the diesel engine as it can uses as:

1. Filter

the ensuring oil from dirt.

2. Meters

the correct quantity of fuel to be injected into the cylinder.

3. Also,

regulates the fuel supply.

4. Atomize

the fuel oil for better mixing with the hot oil.

5. And

finally distribute the atomized fuel properly in the combustion chamber.

• Air intake system:It’s used to transfer fresh air through louvers and air filter to the cylinder by an intake manifold, and we can fit a supercharger driven by the engine between the filter and the engine to augment the power.

• Exhaust system:It’s used to discharge the engine exhaust to the atmosphere with minimum noise.

We use an exhaust manifold to connect the engine cylinder exhaust to the exhaust pipe to demand the fluctuating pressure of the exhaust line with a muffler or silencer to in turn reduces most the noise resulted when gases discharged directly to the atmosphere.There is also a flexible tubing system to take up the facts of expansion and isolate the exhaust system from the engine vibration. And we may also use a heat recovery steam generator to generate low-pressure steam for process work.

• Engine lubrication system:It’s used to provide sufficient quantity of cool filtered oil to give adequate lubrication to the moving parts of the engine, it consists of lubricating oil tank, pump, filter, and oil cooler. and it’s classified into:

1. Mixed lubrication system: it’s usually

used in the two-stroke engine where we mix a small quantity of lubricating oil

in the fuel tank.

2. Wet sump lubrication system: which may

be splash system, pressure fed system or splash or pressure feed system.

3. Dry sump lubrication system: it’s

usually used in a large stationary marine engine where we carry the supply of

oil in an external tank with some help of scavenging pump through a strainer

and filter.

• Cooling system:It consists of a water source; a pump which circulates water through a cylinder and head jacket; and cooling tower in which it can cool the hot water from the engine.

And we must take in consideration

when planning for the layout the following:

• The

approximate dimensions of the equipment.

• Location

of the equipment and the minimum clearance between each part.

• Natural

lighting and proper ventilation provision.

• The

availability of future addition to the building with minimum changes.

• Provision

for installing at least one spare unit in the future.

• And

provision for a small workshop, stores, office and so on.

Application of diesel power plant:

As diesel power station has a

capacity in the range of 2 to 5MW; So, We can use it in many applications as:

• A

central station for medium or small power supplies.

• And

for emergency services as a stand_by plant to hydroelectric power plants and

steam power plants.

• We

can Use with thermal or hydro_power plants as a peak load plant in

combinations.

• For

mobile power generation, transportation systems like automobiles, railways,

airplanes, and ships.

• A

nursery station to transport the power from stations to small power plants, or

supply power to small towns.

• It’s economical for industries where they require a small power in the order of 500 KW as it offers high overall efficiency.

• And

also used for electrical power generation in capacities 100 to 500 H.P.

Advantages of diesel power plant:

The diesel power station is simple in everything so it has

many advantages as:

1. The

low initial cost which makes it easy to quickly install and commission it.

2. The

design is very simple and requires small space.

3. It

can start and stop with quick facilities; as small generators can start and

stop in few seconds without any standby loss in the system.

4. The

thermal efficiency is quite higher than other types.

5. We

can build it near the load center and doesn’t cause a problem of ash disposal

exists.

6. The

size of the plant is quite smaller than steam plants also they have the same

capacity.

7. It’s

easy to design it for portable use.

8. The

cooling is easy and requires a small quantity of water.

9. There

isn’t any difficulty with varying loads.

10. Also,

the fuel cost required for operation is low.

11. Replacement

losses are smaller

12. And

it also requires fewer members of engineers.

Disadvantages of diesel power station:

To be fair, as we illustrate the advantages; we will also

illustrate the disadvantages of the diesel plant which are:

1. The

higher running costs due to the high cost of the diesel.

2. The

general use of this plant is to produce small power requirement.

3. It

can’t stand up for a long period of overload conditions.

4. The

lubricants cost is high.

5. Complex

and high-cost maintenance; which makes the life of the plant small from 7 to 10

years.

6. Its

capacity is only about 50 MW.

7. It’s

difficult to construct it for large scale.

8. Also,

the noise produced by the plant is high.

0 Comments