Impact Test

An impact test is used to observe the mechanics that a material will exhibit when it experiences a shock loading that causes the specimen to immediately deform, fracture or rupture completely. To perform this test the sample is placed into a holding fixture with the geometry and orientation determined by the type of test that is used and then a known weight generally but not always in the shape of a pendulum is released from a known height so that it collides with the specimen with a sudden force. This collision between the weight and specimen generally results in the destruction of the specimen but the transfer of energy between the two is used to determine the fracture mechanics of the material.

An impact test is used to observe the mechanics that a material will exhibit when it experiences a shock loading that causes the specimen to immediately deform, fracture or rupture completely. To perform this test the sample is placed into a holding fixture with the geometry and orientation determined by the type of test that is used and then a known weight generally but not always in the shape of a pendulum is released from a known height so that it collides with the specimen with a sudden force. This collision between the weight and specimen generally results in the destruction of the specimen but the transfer of energy between the two is used to determine the fracture mechanics of the material.

Purpose of impact testing:

The purpose of an impact test is to determine the ability of the material to absorb energy during a collision. This energy may be used to determine the toughness, impact strength, fracture resistance, impact resistance or fracture resistance of the material depending on the test that was performed and the characteristic that is to be determined. These values are important for the selection of materials that will be used in applications that require the material to undergo very rapid loading processes such as in vehicular collisions.

The purpose of an impact test is to determine the ability of the material to absorb energy during a collision. This energy may be used to determine the toughness, impact strength, fracture resistance, impact resistance or fracture resistance of the material depending on the test that was performed and the characteristic that is to be determined. These values are important for the selection of materials that will be used in applications that require the material to undergo very rapid loading processes such as in vehicular collisions.

Types of impact tests:

For a single impact test the three most popular types of test are the Charpy V-notch test, the Izod test and the Tensile Impact test. These three tests all essentially determine the same characteristics of the material but differ in the orientation of the test sample which causes the sample to be stressed in different directions and involve a known weight released from a known height colliding with the specimen in its test fixture. All of these tests are useful in determining the impact mechanics of the test specimen.

For a single impact test the three most popular types of test are the Charpy V-notch test, the Izod test and the Tensile Impact test. These three tests all essentially determine the same characteristics of the material but differ in the orientation of the test sample which causes the sample to be stressed in different directions and involve a known weight released from a known height colliding with the specimen in its test fixture. All of these tests are useful in determining the impact mechanics of the test specimen.

Types of materials for impact testing:

Nearly all materials may benefit from impact testing, but the most common types used are metals, plastics, woods, composites, ceramics, and polymers. Generally these materials take the form of sheets of varying thicknesses or short rods depending on the test. However, most materials will experience either ductile or brittle failure depending of the type of test, the rate of loading and the temperature of the sample. Brittle failure of a material requires a small amount of energy to begin the crack or to cause the crack to grow until the sample fails. On the other hand, ductile failure of a material requires a much higher load to initiate and propagate the crack until failure.

Nearly all materials may benefit from impact testing, but the most common types used are metals, plastics, woods, composites, ceramics, and polymers. Generally these materials take the form of sheets of varying thicknesses or short rods depending on the test. However, most materials will experience either ductile or brittle failure depending of the type of test, the rate of loading and the temperature of the sample. Brittle failure of a material requires a small amount of energy to begin the crack or to cause the crack to grow until the sample fails. On the other hand, ductile failure of a material requires a much higher load to initiate and propagate the crack until failure.

Selected Test Standards

- ASTM D1822 Tensile Impact Energy of Plastic | Test Machines & Equipment

- ASTM D256 Izod Impact Resistance of Plastics

- ASTM D4812 Unnotched Pendulum Impact of Plastic Test Machine

- ASTM D6110 Charpy Impact Resistance of Notched Specimens of Plastics

- ISO 13802 Pendulum Impact Test of Plastics | Machines

- ISO 179 Charpy Impact Strength of Notched Plastics | Testing Equipment

- ISO 180 Izod Impact Strength of Plastic | Test Equipment

- ISO 7765-1 Impact Resistance of Plastic Sheet and Film | Testing Equipement

- ISO 8256 Tensile Impact of Plastics Test Equipment

- ASTM D1822 Tensile Impact Energy of Plastic | Test Machines & Equipment

- ASTM D256 Izod Impact Resistance of Plastics

- ASTM D4812 Unnotched Pendulum Impact of Plastic Test Machine

- ASTM D6110 Charpy Impact Resistance of Notched Specimens of Plastics

- ISO 13802 Pendulum Impact Test of Plastics | Machines

- ISO 179 Charpy Impact Strength of Notched Plastics | Testing Equipment

- ISO 180 Izod Impact Strength of Plastic | Test Equipment

- ISO 7765-1 Impact Resistance of Plastic Sheet and Film | Testing Equipement

- ISO 8256 Tensile Impact of Plastics Test Equipment

Selected Applications

- Charpy Impact Strength of Plastics | Testing Equipment

- Izod Impact Strength of Plastics | Testing Equipment

- Plastics Thin Film & Sheet Tensile Tear Impact Testing

- Charpy Impact Strength of Plastics | Testing Equipment

- Izod Impact Strength of Plastics | Testing Equipment

- Plastics Thin Film & Sheet Tensile Tear Impact Testing

Charpy Impact Test

At WMT&R, Izod and Charpy impact testing are performed on instrumented machines capable of measuring less than 1 foot-pound to 300 foot pounds at temperatures ranging from -320°F to over 2000°F. Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of testing subsize specimens down to ¼ size. IZOD impact testing can be done up to 240 foot-pounds on standard single notch and type-X3 specimens.

The Charpy Impact Test was invented in 1900 by Georges Augustin Albert Charpy (1865-1945). The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. The Charpy impact test continues to be used as an economical quality control method to determine the notch sensitivity and impact toughness of engineering materials.

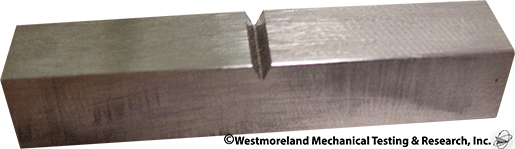

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions.

- V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base

- U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch

The Charpy Impact Test consist of striking a suitable specimen with a hammer on a pendulum arm while the specimen is held securely at each end. The hammer strikes opposite the notch. The energy absorbed by the specimen is determined by precisely measuring the decrease in motion of the pendulum arm.

Important factors that affect the toughness of a material include: low temperatures, high strain rates (by impact or pressurization), and stress concentrators such as notches, cracks and voids.

By applying the Charpy Impact Test to identical specimens at different temperatures, and then plotting the impact energy as a function of temperature, the ductile-brittle transition becomes apparent. This is essential information to obtain when determining the minimum service temperature for a material.

The Charpy Impact Test was invented in 1900 by Georges Augustin Albert Charpy (1865-1945). The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. The Charpy impact test continues to be used as an economical quality control method to determine the notch sensitivity and impact toughness of engineering materials.

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions.

- V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base

- U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch

The Charpy Impact Test consist of striking a suitable specimen with a hammer on a pendulum arm while the specimen is held securely at each end. The hammer strikes opposite the notch. The energy absorbed by the specimen is determined by precisely measuring the decrease in motion of the pendulum arm.

Important factors that affect the toughness of a material include: low temperatures, high strain rates (by impact or pressurization), and stress concentrators such as notches, cracks and voids.

By applying the Charpy Impact Test to identical specimens at different temperatures, and then plotting the impact energy as a function of temperature, the ductile-brittle transition becomes apparent. This is essential information to obtain when determining the minimum service temperature for a material.

1 Comments

Jost’s material handling provides innovative solutions for internal material handling needs for its customers so that it improves the efficiencies of their processes.

ReplyDeleteShock Testing Machines of various capacities to be used in the design and destructive testing of components, hybrids, circuits, and complete assemblies. These machines are used testing a variety of products from Aerospace, Millitary, Industrial and consumer

Shock Testing Machines